At the beginning of April 2021, the management of Siemens Mobility Romania – Florian Paul Roettig, CEO Siemens Mobility SRL & Adrian Stoica, CFO Siemens Mobility SRL, were invited to participate to a public consultation in the presence of members of the Ministry of Transportation regarding the renewal of rolling stock through the National Recovery and Resilience Plan 2021-2026.

„Reducing emissions from transport and decarbonization of transport will be essential in the race against climate change. Siemens Energy and Siemens Mobility are working together to develop holistic solutions for a sustainable hydrogen infrastructure that will be used to power Siemens Mobility’s hydrogen trains” says Florian Roettig, CEO of Siemens Mobility SRL.

The European Green Deal is a plan to make the EU’s economy more sustainable. Because the transport sector is currently responsible for around 25 % of the Union’s greenhouse gas emissions, one of its key elements focuses on rolling out cleaner and healthier means of transport. The European Green Deal aims at a 90 % reduction in transport emissions by 2050.

50 % of the European railway network is currently non-electrified, with more than 800 diesel locomotives and diesel trains still in operation in Romania alone. Consequently, the country is presently considering replacing part of its rolling stock fleet with state-of-the-art hydrogen, battery and/or electric-powered trains. During the public consultation, Siemens Mobility discussed the environmental, technical, and financial aspects of such a possible future acquisition with representatives of the Ministry of Transportation.

Hydrogen vs. Electricity – what is the best use-case?

The highest efficiency – up to 76 % – is provided by purely electric-driven trains. The production, transportation, and storage of hydrogen, on the other hand, consumes more energy. This leads to the efficiency of hydrogen-based solutions being at around 30 %. The optimum solution, in either case, is to use “green” energy for train operation, for example wind, solar or waterpower.

A decision concerning the operation of a hydrogen-powered or battery-powered train on a non-electrified track requires the proper use-case analysis. If, for example, a sustainable train connection between Gara De Nord and the Henry Coanda airport should be established, then Siemens Mobility would recommend considering the usage of a battery-driven train. This recommendation is based on the fact that the distance between the two stations, which amounts to 19 km, is relatively short. Furthermore, Siemens Mobility’s battery-driven trains can also be used like regular EMUs (Electric Multiple Units): The batteries can be charged by means of a pantograph within 15 minutes and they can run up to 120 km solely on batteries. Summing up, the main advantages are that battery-driven trains do not require any additional infrastructure such as e.g., hydrogen production and hydrogen refueling stations and that such a train can also be used like an EMU. This leads to smaller infrastructure investments than those required for a hydrogen train.

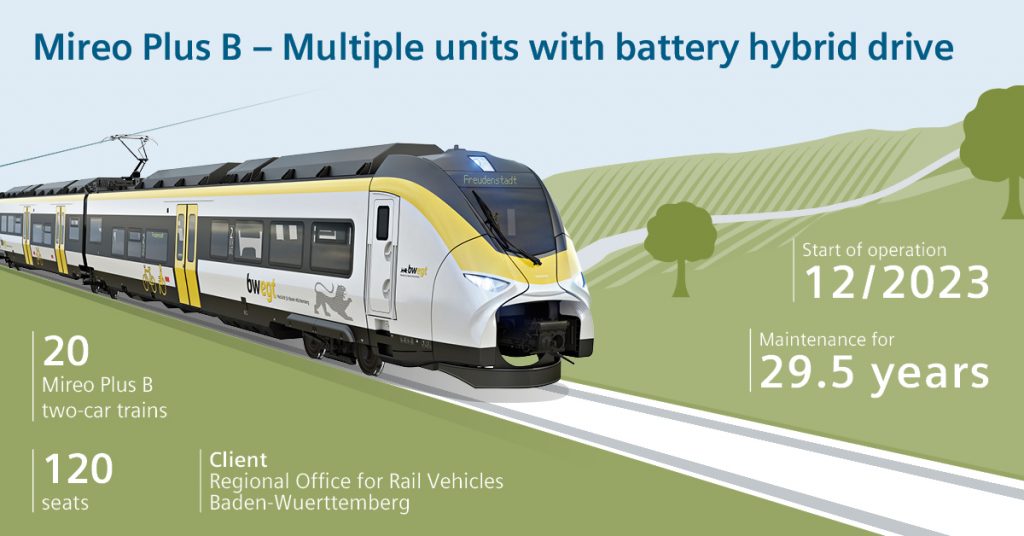

Siemens Mobility offers two types of battery trains and a brand-new hydrogen train

The Mireo Plus B is an electric multiple unit train for regional transport, which draws its energy from the overhead line or from battery systems housed in containers located beneath the floor. It uses lithium-ion batteries with a long service life. Under real-life conditions, while operating with batteries at speeds up to 160 km/h, the two-car, 120-seat train has a range of around 80 to 90 kilometers. The three-car version with 165 seats can even operate across distances of 100 to 120 kilometers, running on batteries at the same speed.

Compared to a similar diesel-powered trainset, the Mireo Plus B saves an average of 24 tons of CO2 per year. Despite the extra expense for the battery system, the break-even point for CO2 savings is already reached for trains averaging 200,000 kilometers a year within one and a half years.

The Mireo Plus B is based on the experiences gained by Austrian Federal Railways (ÖBB) and Siemens Mobility in the development of an electro-hybrid battery system since 2018. The three-car Desiro ML eco prototype, based on the electric Desiro ML from Siemens Mobility, and with a battery container installed on the roof, was premiered at the InnoTrans in September 2018.

The prototype hybrid train was awarded unrestricted approval for passenger operation in August 2019 and has been running on various main and branch routes in Austria ever since. Around a quarter of the country’s branch lines, totaling roughly 1,300 kilometers, are not electrified. Drawing on energy from its batteries, the prototype reaches a top speed of 120 km/h (160 km/h operating with overhead lines) and has been a success with both ÖBB and its passengers. The goal of the project has been to gain extensive experience with the operation of alternative drive systems under all conditions in summer and winter. The Desiro ML eco charges its batteries from overhead lines while en route and during stops.

Mireo Plus H: Hydrogen is an excellent energy source with a high energy density. In other words, a significant amount of energy per volumetric unit can be stored in hydrogen (assuming a corresponding compression) and recovered in the fuel cell as electricity. Within Siemens Mobility’s portfolio of hybrid drive systems for commuter and regional trains, the Mireo Plus H is therefore the solution most suited for long-distance routes. Whereas Mireo Plus B trains are the best choice for distances of up to 120 km (depending on configuration), Mireo Plus H trains achieve ranges of up to 600 km as two-part trains, and from 800 to 1,000 km as a three-part train, depending on the line profile and mode of operation.

The operation of a hydrogen-driven train would, for example, be feasible between Gara de Nord and the City of Pitesti (a round-trip of approximately 240 km) as well as on any other railway line with a distance of up to 1,000 km.

The Mireo Plus H hydrogen train, developed by Siemens Mobility, meets demanding operational requirements without an overhead catenary. Quiet and clean, the Mireo Plus H combines reliable, sustainable traction with superior passenger comfort and optimal life cycle cost-efficiency. As a train developed specifically for operation with a fuel cell right from the start, it has a leading edge in many areas.

The Mireo Plus H features everything required to operate independently of an overhead contact line, including an optimally dimensioned and safe hydrogen tank, an efficient fuel cell for generating clean electricity, and powerful drives for extremely high acceleration values. Mireo Plus H can be operated just like a conventional train: but without emissions. Even refueling with hydrogen takes no longer than it does with a comparable diesel train. Furthermore, opting for green hydrogen fuel generated from renewable sources leads to zero CO2 emissions.

Article published in partnership with Siemens Mobility SRL